Every industry. Every medium. A suitable solution.

Your processes are demanding – and so are our IBC systems. Whether liquids or bulk goods, whether pharmaceuticals, chemicals, food or special applications: With UCON, you don’t just get a container, but a system that thinks for you. Developed to integrate – into your processes, your standards, your requirements.

Do you need precise dosing? Controlled emptying? Or a cleaning system that you can rely on in continuous use? We work with you to develop precisely the system that makes your processes safer, more efficient and simpler.

The result:

Functioning solutions instead of compromises

Stainless steel quality, double-walled or with special equipment on request

Freedom of choice in terms of volume, valve technology, control and cleaning

Personal advice from a team that listens

No matter what industry you work in – our IBC systems are designed for real practice. We don’t want you to adapt to us. We should adapt to you.

IBC-Systems

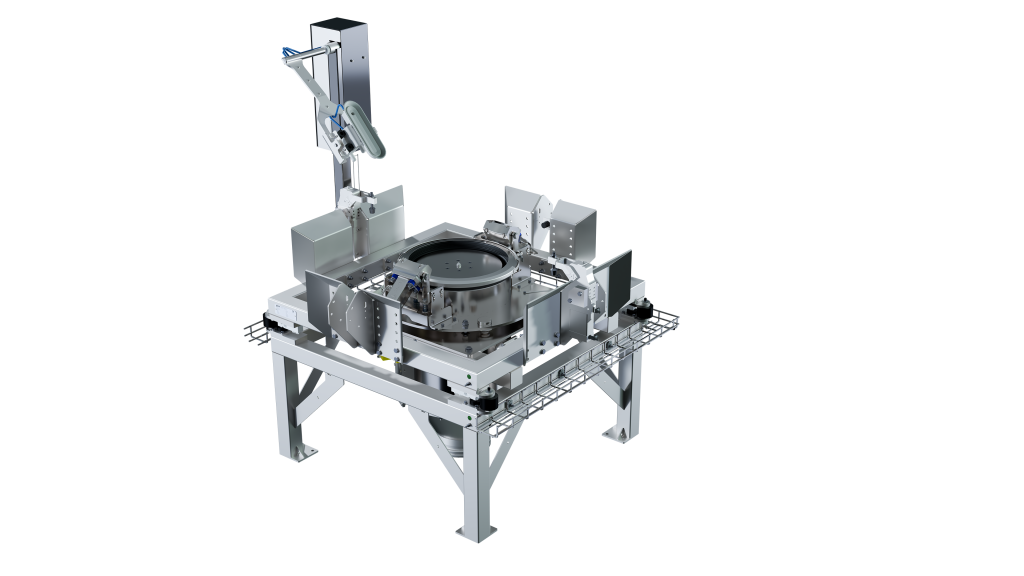

Our automated solution for transferring big bags into UCON containers enables precise dosing or complete emptying – tailored to your process requirements. Whether for repacking into IBCs or for direct further processing, the system ensures controlled, safe material transfer with the highest OEB requirements.

Einfache Reinigungsprozesse für alle IBCs, Ventile und Schnittstellensysteme, um Hygiene zu gewährleisten und Kreuzkontaminationen zu vermeiden

UCON Container System GmbH

Gustav-Rivinius-Platz 2

77756 Hausach

Deutschland

Tel: +49 7831 77-0

E-Mail: info@uconcs.com